Facilities

SCREW COMPRESSOR LABORATORY

Test rigs are built to meet CAGI and PNEUROP test standards and test procedure meet ISO 1217:2009 +A1:2016(E) standard (Displacements compressor – Acceptance tests).

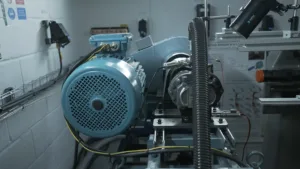

The oil-injected test rig is equipped with a 2 pole AC motor of 75 kW with maximum rotational speed of 3600 rpm and torque up to 250 Nm. The compressor is driven through a belt pulley train drive.

The oil-injected screw compressors can be tested to the discharge pressure of up to 12 bar (g) and discharge temperature up to 100 oC. Air-oil mixture is separated after the discharge using a two stages oil separator (centrifugal + filter). The test rig is equipped with an oil-cooler to reduce oil temperature to a specified temperature.

The oil free test rig is equipped with a 4 pole AC motor of 75 kW with maximum rotational speed of 1800 rpm and torque up to 500 Nm. The compressor is driven directly by the motor.

Oil-free screw compressors can be tested to the discharge pressure up to 2.8 bar (g and discharge temperature up to 200 oC. The maximum delivery airflow is 1000 m3/h (588 cfm).

High-frequency data acquisition system (NI cRio) accompanied by LabView allows testing in a steady-state or transient conditions, and for loaded or unloaded compressor, with real-time calculation of performances and monitoring of the compressor.

- Pressure (suction and discharge).

- Temperature (suction, discharge, oil injection).

- Delivered airflow (Orifice plate – IS0 5167-2:2003 and PD ISO/TR 15377:2018).

- Torque and rotational speed.

- Oil flow rate.

- Other capabilities: Dynamic pressure (Inside the compressor can allow plotting P-alpha diagram), Noise measurement, Mechanical vibration measurements

After testing, an extensive report is prepared to present a test rig setup, tested compressor, and test conditions (pressure, temperatures, speeds). Measurements are shown in a standard form of performance maps and plotted in function of speed or delivery. All other details are also included in the report.

Special capabilities/abilities on request:

- 4 pole AC motor of 75 kW and 500 Nm is available.

- Test of other machines (scroll and vane compressor, roots blower, twin-screw expander…)

- Testing with different oils

OPTICAL COMPRESSOR LABORATORY

State of the art optical laboratory is specifically dedicated to study the flow field and Heat transfer phenomena in leakage flows as well as main flow in actual running condition of the positive displacement machines using high-end techniques such as Particle image velocimetry (PIV), High speed infrared thermography (IR) and Planar laser induced fluorescence (PLIF). This enables us to understand the flow physics inside the rotary machines. This facility can be leveraged to other applications such as turbines and aerodynamics.

INTERNALLY-GEARED MACHINES LAB

Currently, at City, a new test laboratory is being established to investigate a revolutionary new type of screw machine. An in-house designed testbed will allow testing of oil-injected IGSM with power up to 11kW. Internally-geared screw compressors have a number of potential advantages over conventional twin-screw configurations, including reduced leakage areas, co-directional thermal expansion, reduced rotor deflection, reduced viscous losses, and higher swept volume for a given machine envelope. Laboratory is expected to be ready by the end of 2024 and first test will start in the beginning of 2025.

REFRIGERATION AND ORC TEST LAB

for compressors, expandors and turbines

The expander test facility is a modified vapour-compression system with partial cooling/condensation using modern refrigerants. This test facility can replicate typical operating conditions within an ORC system, and will be used to conduct experiments on two-phase expansion using twin-screw expanders.